Introduction

Refrigerators today are no longer simple cooling boxes. They are smart appliances controlled by electronic brains known as PCB boards. When this board fails, the entire refrigerator can stop working or behave unpredictably. Understanding Refrigerator Repair For Pcb Board Malfunction Tips & Common Mistakes is essential for homeowners, technicians, and appliance service providers.

PCB board issues are among the most misdiagnosed refrigerator problems. Many units are replaced unnecessarily due to lack of technical knowledge. This guide explains how PCB boards work, why they fail, and how to repair them correctly while avoiding common errors. The goal is to help you save money, time, and frustration through informed decision-making.

Understanding the Role of a Refrigerator PCB Board

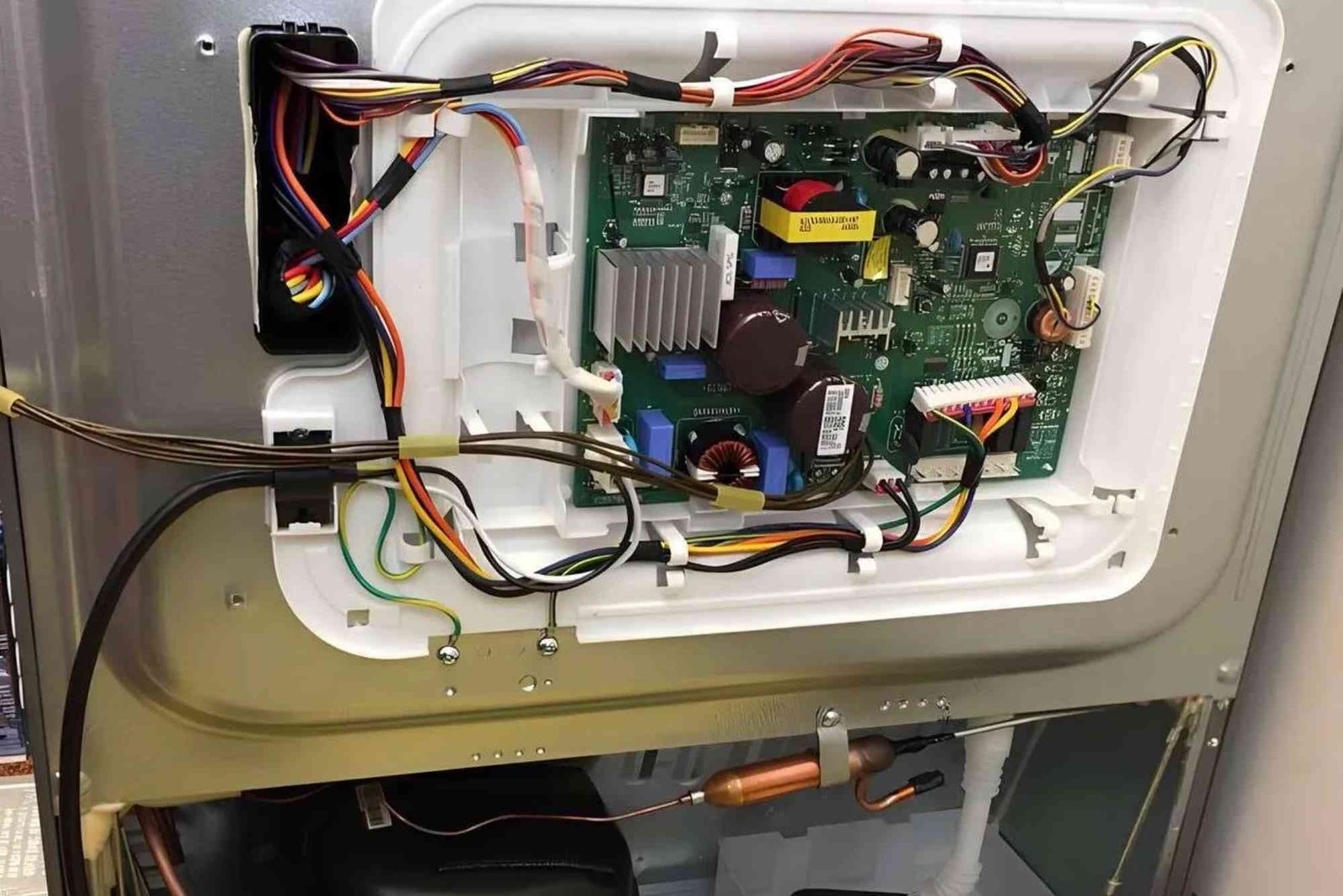

A PCB board, also called a control board, manages all electronic functions of a refrigerator. It controls temperature sensors, compressors, fans, defrost cycles, and display panels. Modern inverter refrigerators rely heavily on PCB accuracy.

When the PCB board fails, the refrigerator loses its ability to regulate operations. This often leads to inconsistent cooling, error codes, or complete shutdowns. Knowing how this board interacts with other components is the foundation of effective refrigerator repair for PCB board malfunction tips & common mistakes.

How PCB Boards Control Refrigerator Operations

The PCB receives signals from sensors and sends commands to mechanical parts. For example, when the internal temperature rises, the PCB activates the compressor. If the defrost sensor detects ice buildup, the PCB initiates defrost mode. A single damaged circuit can disrupt these actions.

Why PCB Boards Are Sensitive Components

PCB boards are vulnerable to voltage fluctuations, moisture, dust, and heat. Even minor power surges can burn microchips or tracks. This sensitivity makes professional handling critical during repairs.

Common Symptoms of PCB Board Malfunction in Refrigerators

Recognizing early symptoms prevents major breakdowns. PCB-related faults often show warning signs before complete failure.

Refrigerator Not Cooling Properly

When cooling becomes inconsistent, the PCB may not be sending accurate signals to the compressor or fan motors. This is a classic sign technicians check first.

Display Panel Not Working or Showing Errors

Blank screens, flickering displays, or error codes usually indicate control board issues. Error codes are often misunderstood and lead to incorrect part replacement.

Refrigerator Turning On and Off Randomly

Sudden shutdowns or continuous restarting point to unstable PCB power circuits. This can worsen if ignored.

Compressor Running Continuously

A faulty PCB may fail to stop the compressor, causing excessive cooling and high electricity bills.

Major Causes of PCB Board Failure

Understanding causes helps prevent repeat failures after repair. Many mistakes happen because root causes are ignored.

Voltage Fluctuations and Power Surges

Unstable electricity is the leading cause of PCB damage. Sudden surges burn delicate components instantly.

Moisture and Humidity Exposure

Water leaks, condensation, or high humidity can corrode PCB tracks. Corrosion often causes delayed failures.

Overheating Due to Poor Ventilation

PCB boards generate heat during operation. Poor airflow around the refrigerator increases board temperature and shortens lifespan.

Poor Quality Repairs or Fake Parts

Low-quality soldering and counterfeit components weaken the board. These shortcuts often lead to repeated breakdowns.

Refrigerator Repair For Pcb Board Malfunction Tips & Common Mistakes Explained

Effective repair requires skill, patience, and the right approach. Unfortunately, many technicians repeat the same errors.

Diagnosing the PCB Instead of Guessing

One major mistake is replacing the PCB without testing. Proper diagnosis includes voltage testing, sensor verification, and visual inspection. Guesswork leads to wasted money.

Repairing Instead of Replacing When Possible

Not every PCB needs replacement. Burnt resistors, damaged capacitors, and broken tracks can often be repaired. Skilled technicians can restore boards at lower cost.

Using Proper Tools and ESD Protection

Static electricity can damage sensitive PCB components. Many failures happen during handling, not operation. Anti-static gloves and tools are essential.

Avoiding Incorrect Soldering Techniques

Excessive heat during soldering damages nearby components. Cold solder joints cause unstable connections. Precision is key.

For a deeper technical explanation, you can read this in-depth look at refrigerator repair for pcb board malfunction at which explains real-world repair scenarios.

Step-by-Step Professional Approach to PCB Repair

Professional technicians follow structured methods rather than shortcuts. This reduces errors and increases repair success.

Initial Inspection and Error Code Analysis

Technicians begin by reading error codes and inspecting connectors. Loose wiring often mimics PCB failure.

Testing Power Supply and Sensors

Before blaming the PCB, power input and sensor outputs are tested. Many PCB boards are replaced due to faulty sensors.

Component-Level Repair Process

Damaged capacitors, ICs, or relays are identified and replaced. Tracks are repaired using jumper wires when needed.

Final Calibration and Performance Testing

After repair, the refrigerator is tested under load. Temperature stability and compressor cycling confirm success.

Common Mistakes to Avoid During PCB Board Repair

Even experienced technicians can make errors. Awareness reduces risk.

Ignoring the Root Cause

Replacing a PCB without fixing voltage issues leads to repeat failure. Always address power stability first.

Using Non-Compatible PCB Boards

Different refrigerator models use different firmware. Installing the wrong PCB causes new faults.

Skipping Post-Repair Testing

Some repairs fail because testing is rushed. Long-term testing ensures reliability.

DIY Repairs Without Technical Knowledge

Online videos encourage DIY PCB repair. Without training, this often damages the board beyond repair.

When to Repair and When to Replace the PCB Board

Decision-making depends on damage severity, cost, and refrigerator age.

Situations Where Repair Is Ideal

Minor burns, faulty capacitors, or broken tracks are repairable. Repair is cost-effective and environmentally friendly.

Situations Where Replacement Is Better

Severely burnt boards, corrupted firmware, or multiple damaged ICs often require replacement. Safety should come first.

Preventing Future PCB Board Malfunctions

Prevention saves more money than repair. Simple steps protect your refrigerator’s control board.

Use a Voltage Stabilizer or Surge Protector

Stabilizers regulate power supply and protect sensitive electronics. This is highly recommended in areas with unstable electricity.

Ensure Proper Ventilation Around the Refrigerator

Adequate airflow prevents overheating. Avoid placing refrigerators too close to walls.

Schedule Periodic Professional Maintenance

Routine inspections detect early signs of PCB stress. Maintenance extends appliance life significantly.

For broader appliance care and lifestyle guidance, explore home & decoration basics at to maintain a healthier home environment.

Expert Insights Based on Field Experience

Technicians with years of experience agree that PCB failures are increasing due to smart appliance complexity. Modern refrigerators require electronic expertise, not just mechanical skills. Choosing trained professionals ensures accurate diagnosis and long-term reliability.

Appliance service providers collaborating with experienced platforms and an editorial partner like often emphasize education-driven repairs rather than unnecessary replacements.

Frequently Asked Questions

Can a refrigerator work with a damaged PCB board?

No, the PCB controls all major functions. A damaged board causes partial or complete failure.

How much does refrigerator PCB repair cost?

Costs vary by damage level. Repairs are usually cheaper than full board replacement.

Is PCB repair safe for inverter refrigerators?

Yes, when done by trained professionals using proper tools and testing methods.

How long does a repaired PCB board last?

A properly repaired PCB can last several years if voltage issues are resolved.

Should I replace the refrigerator if the PCB fails?

Not necessarily. PCB repair is often more economical than buying a new refrigerator.

Choose Smart Repairs Over Costly Mistakes

Understanding Refrigerator Repair For Pcb Board Malfunction Tips & Common Mistakes empowers you to make informed decisions. PCB boards are complex but repairable components when handled correctly. Avoid guesswork, address root causes, and rely on experienced technicians for lasting results.

If your refrigerator shows signs of PCB trouble, act early. Professional diagnosis can prevent complete failure and reduce costs. Contact a qualified appliance repair expert today and protect your refrigerator investment before small issues become major problems.